External Brief

- remicatchpole

- Nov 17, 2021

- 3 min read

Updated: Dec 3, 2021

This blog post will show the progress I have made since starting my project. It will also include drawing analysis, initial problem finding, design development, and drawing interpretation.

These set of sketches and workings outline the model dimensions that I will be working to, the different materials that could be used, and the effectiveness of the various types of finishes that could be used. They also compare the advantages and disadvantages of the potential processes, methods, and techniques that could be used to produce this model. Furthermore, it identifies the issues that may occur during these processes and how I might go about resolving them.

The majority of the problems that I have faced so far have been to do with re-modelling and re-surfacing the CAD model so it can be CNC routed. The main issue being that I had to split the model into separate components, meaning that these poly surfaces were not watertight. However, through lots of advice and tutorial guides I was eventually able to fix these problems. Although, it significantly reduced the time I now have to finish the remaining parts of the model, meaning that I now have to work as efficiently as I can.

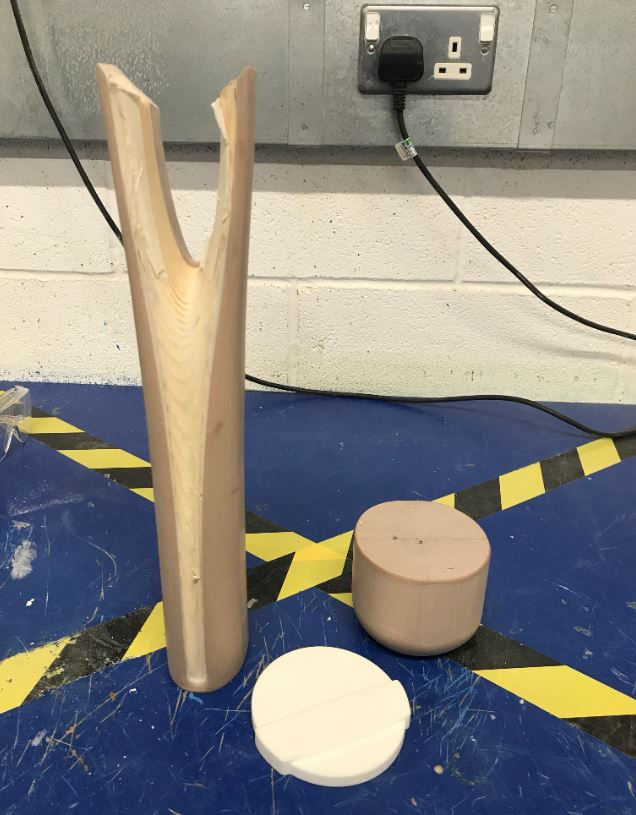

Another set back I had was that some parts of the CAD model that had been CNC routed came out inaccurate. The inner stem piece which was cut out of cedar wood was chipped in some areas, this meant that I had to try and fill them with near identical pieces of wood. On the other hand, the front half of the outer stem piece was

re-modelled slightly too wide which meant that I had to cut back and sand it down. Overtime, I was able to achieve the correct dimensions and required quality of finish for these pieces. Even though this decreased the time I had to finish the outstanding parts of the model.

These set of images consist of the font and logo design for the badge lens, the logo design for the handle, and the text font design for the stem of the beer pump. These have been designed to attract the core target audience of 18-35 year old men, making the beer brand desirable for this demographic. I will be also be adding LED lights round the outside of the badge lens so the design can function effectively in both a light airy venue and dark club environment.

The next step is to firstly, finish producing the remaining parts of the model, some of these will be hand made and other more complicated pieces will be 3D printed. This involves filling and sanding back all the pieces accurately to the exact dimension whilst attaining the best quality of finish possible. I will also need to print off the badge lens font and logo design in colour to the right dimension to place onto the model. A piece of clear acrylic will be positioned on top of this before installing the LED lights. The logo design for the handle and the text font design for the stem of the beer pump will need to be printed off to the correct size. I will then use these as stencils to engrave the model. To finish, once this has all been complete, I will taint and varnish all the cedar wood pieces, as well as priming and spray painting all the other surfaces black, before painting them metallic chrome.

Comments